目次

Craft Report

Master of Kyoto Blades, YOSHISADA: A Legacy of 360 Years.

Founded in the mid-Edo period in Kyoto’s Higashiyama district, “Yoshisada Knives” has carried on the high-level techniques of blade-making for about 360 years. Today, the workshop is located in Kumiyama, southern Kyoto, where the tenth-generation craftsman Teiichirō Yamaguchi and two young artisans continue to handcraft the few remaining traditional “Kyoto blades.”

A Craftsman Spirit Honed for Over 70 Years.

Teiichirō Yamaguchi, the 10th-generation master, grew up watching his father at work and began training at the age of 15. When his father passed away at only 49 due to illness after surviving the war, Yamaguchi took over the family craft at age 27. “There were still live-in apprentices then, so I had no choice but to carry on,” he recalls.

About 50 years ago, the workshop relocated to Kumiyama, once an airfield during the war. While many traditional Kyoto blade workshops had disappeared, Yamaguchi has continued forging blades for over 70 years, earning the Medal with Yellow Ribbon from the Emperor in 2011. Today, the workshop produces a wide range of blades—from household kitchen knives to specialized knives for professional chefs and tools essential for traditional crafts.

Sharpness and Durability: The Mark of Kyoto Blades.

Kyoto’s geography as the imperial capital provided access to high-quality raw materials such as iron sand, tamahaganesteel, clay, whetstones, and fresh water—ideal conditions for developing blade-making. Originally rooted in swordsmithing, the craft evolved into making practical kitchen knives and other everyday tools.

The process begins by heating base iron and steel at high temperatures, then hammering and shaping them together. This step, known as hi-zukuri (forging), is one of the most difficult and requires extensive experience. Once the blade is formed, it is coated with a special clay mixture of soil and pine charcoal, reheated, and quenched in water—an essential step (yakiire) that hardens the blade and ensures razor-sharp sharpness.

The unique clay composition developed at Yoshisada gives the knives both their cutting power and distinctive color tones. Finally, the blades are polished to perfection with grinders and natural whetstones. The result: blades of exceptional hardness, durability, and a sharp edge that lasts.

Preserving Tradition While Embracing Innovation.

At Yoshisada, blades are made for both everyday households and top-level professional chefs at renowned restaurants. In recent years, overseas demand has surged, with so many orders that production struggles to keep up, including numerous requests for resharpening. Beyond kitchen knives, the workshop also produces tools for traditional crafts, fittings for the Gion Festival floats, and much more.

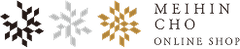

A knife used for cutting tatami mats.

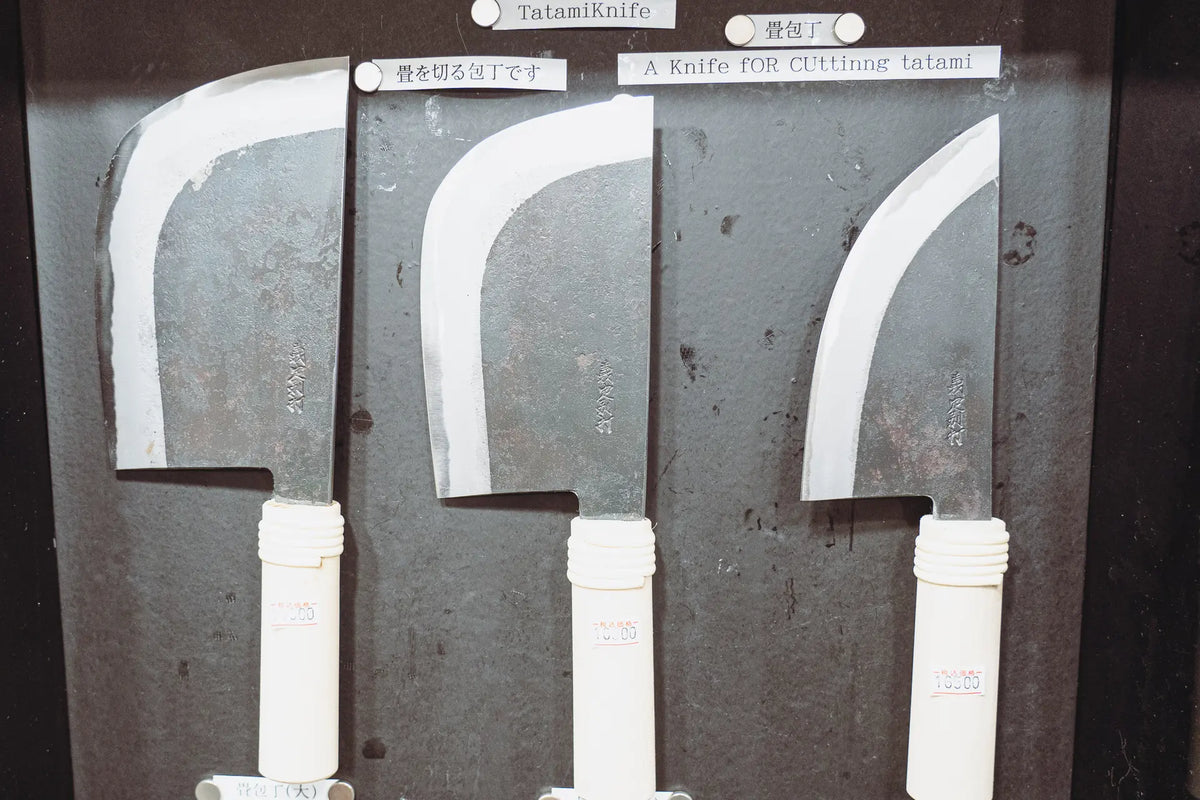

An outdoor utility knife.

Every order demands different approaches—variations in weight, hardness, and shape tailored to the customer’s needs. Some tools can only be made by Yamaguchi himself. “A good blade must cut well and be easy to use. Beyond kitchen knives, we must be ready to make anything the customer requires,” he explains. This flexibility is rooted in decades of experience and is difficult to pass on to younger generations.

For Yoshimura, who has worked at the workshop for 18 years, the greatest satisfaction comes from tackling something new. Recently, he successfully crafted an unusual blade ordered for automobile parts manufacturing—an achievement that led to repeat orders. An outdoor enthusiast, he also develops innovative products such as outdoor knives and palm-sized mini knives. These new creations, blending tradition with modern needs, sell out instantly. “To keep Yoshisada alive, I want to keep creating things that have never existed before,” he says.

Shirai, with 15 years at Yoshisada, continues to refine his skills. “Much of this craft can’t be explained in words—you just have to keep practicing and accumulating experience,” he notes. “What I love is stripping away waste to create something sharp and useful. Even when repeating the same tasks daily, I can feel my precision and skill improving.”

Drawing on centuries-old Kyoto techniques while taking on new challenges, Yoshisada Knives continues to produce blades that support users across generations. From household kitchens to global craftsmanship, their knives remain indispensable tools.

The Yoshisada shop in Shichijō, Kyoto.

Interview, text and photography by Kento Onishi