目次

Craft Report

A Self-Taught Journey into a 300-Year Tradition: Pure Copper Graters.”

In Wakayama, Kishū Shinke continues the 300-year tradition of crafting pure copper graters, each one painstakingly hand-hammered.

The grater is a tool unique to Japanese culture, but today, including Kishū Shinke, there are only about four specialist workshops left in the entire country. Craftsman Takayuki Shinke’s pure copper graters have gained recognition for their evolution beyond conventional designs. Loved not only by households but also by professional chefs across Japan, they embody his ambition of becoming “the world’s best,” hammered into each individual tooth.

Shinke spent nearly 30 years in architecture and landscaping before teaching himself the craft of hand-hammered graters in 2017. An avid mountaineer, he often encountered traditional crafts during his travels and eventually discovered the grater. At the time, he was still working in construction, but with a strong desire to create something only he could make—to become truly unique in the world. Learning that the craft of graters was in danger due to the aging of artisans and lack of successors, he decided to devote himself to preserving it.

Craftsman Takayuki Shinke.

Cutting copper sheets before they become graters.

Evolution in Design and Function: GOOD DESIGN AWARD Winner.

Shinke redesigned the grater, enabling multiple uses—resting it on the palm, gripping its handle, placing it flat, or hooking it onto a container. The grating surface was also expanded. With this innovative approach, he won the Good Design Award in both 2018—just one year after becoming a grater craftsman—and again in 2021.

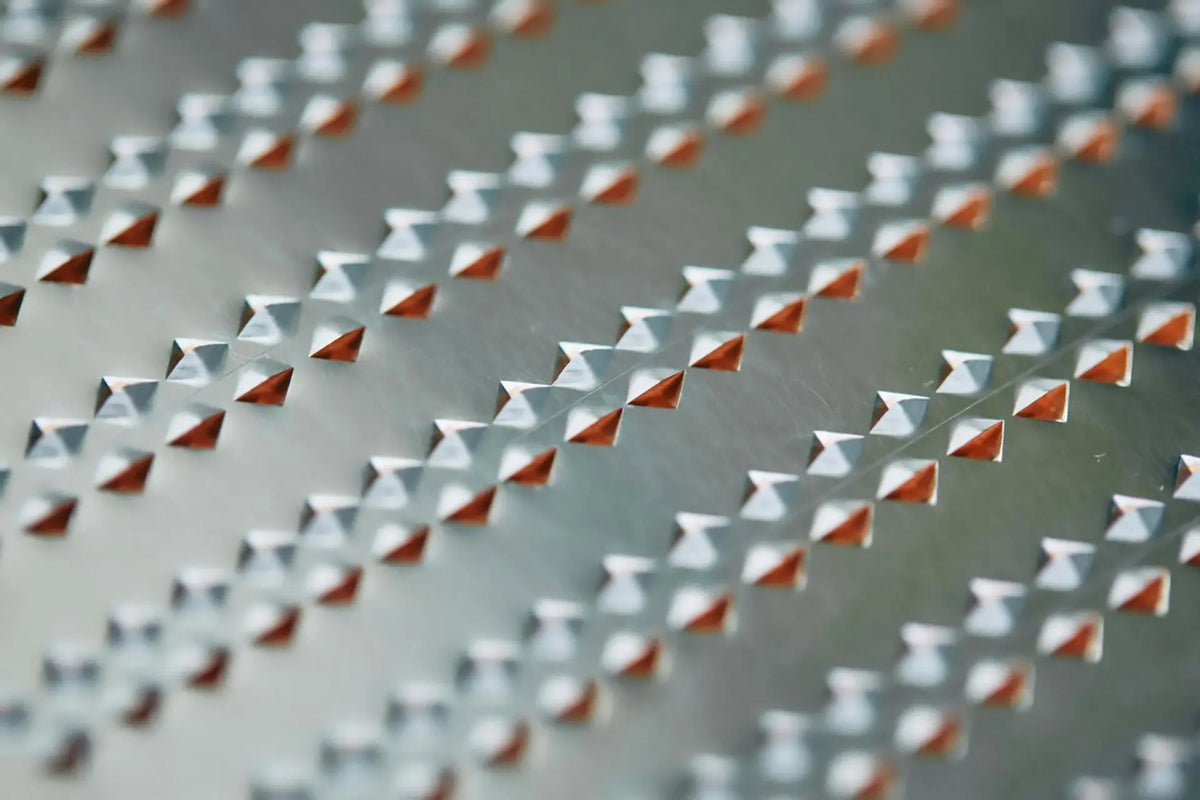

Another hallmark is the mirror finish achieved by coating the copper surface with tin. Traditional dustpan-shaped graters often left chefs’ hands smelling of copper, but the tin coating solved this. Copper itself is strong, workable, and naturally antibacterial thanks to copper ions. The added tin layer further reduces bacterial adhesion, making the graters even more hygienic. Yet tin is soft—over-polishing exposes the copper beneath—so creating this flawless mirror finish requires great skill, blending functionality with beauty.

Applying a tin coating over copper.

Shinke’s workshop includes a corner with toy cars and Ultraman figures for his grandchildren, reflecting his warmth and personality.

The Golden Ratio of Teeth: Unlocking Flavor.

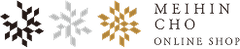

Through relentless research and experimentation, Shinke perfected the ideal size, width, and shape of the grater’s teeth—creating a “golden ratio” unique to Kishū Shinke. The teeth are not razor-sharp, making them safe to touch, but they act more like blades that cut rather than crush. This preserves the fibers and cells of ingredients, releasing their flavors while keeping freshness intact.

A tagane chisel used to raise the teeth.

“Crafting Graters Loved by Chefs Worldwide.”

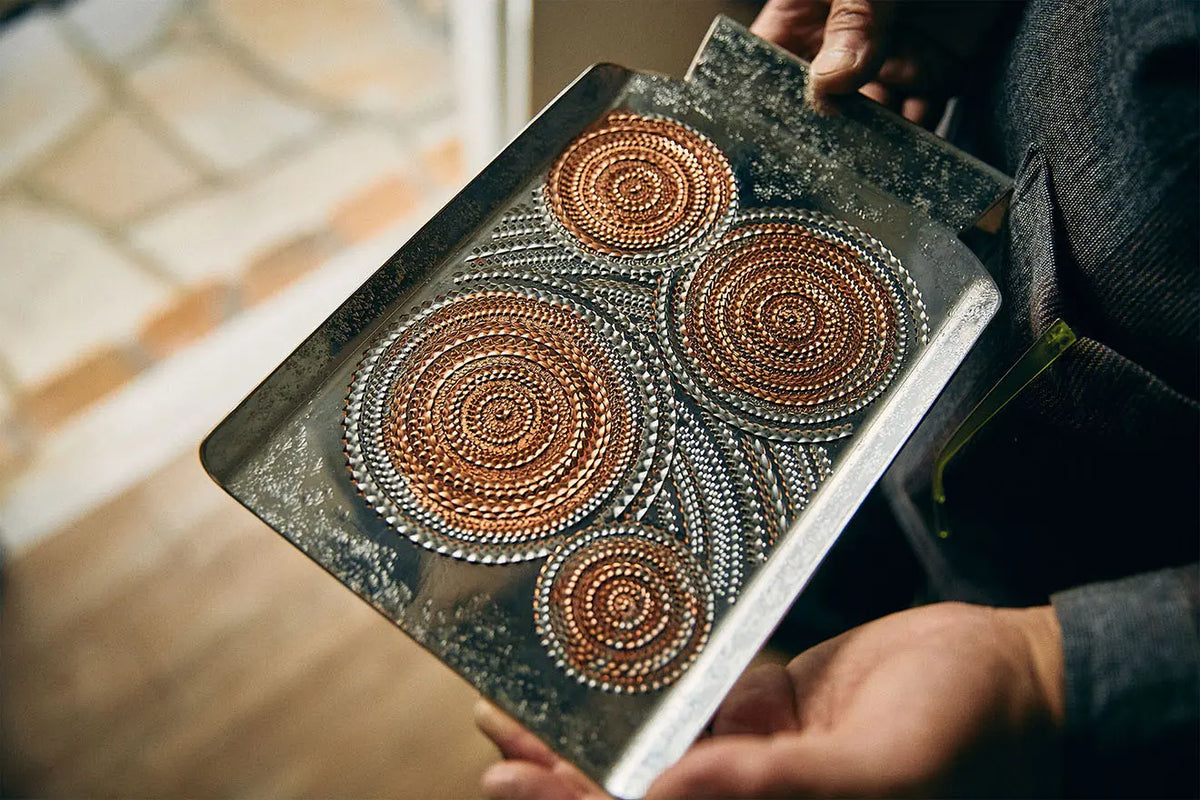

After making thousands of graters, Shinke has developed an intuitive sense: “This one will give a crunchy texture, this one will make it spicier, this one sweeter.” He is so immersed in the world of graters that they almost “speak” to him. His ultimate goal is to become “the world’s best craftsman,” with his graters used by chefs everywhere. To achieve this, he not only creates but also actively promotes his work—seeking media coverage, learning communication skills, and breaking out of his shell. Today, he continues to pursue both functionality and artistry, producing works like the Takumi Series, which resemble art pieces as much as tools.

By adjusting tooth size, width, and shape, he creates graters suitable for a wide range of foods. He also takes custom orders based on chefs’ requests. Even with something as simple as grated daikon, his graters can produce everything from airy, fluffy textures to coarse, crunchy ones. Unlike mass-produced graters, his hand-hammered graters roll the food across the surface while grating—thanks to a unique sawing-like motion—resulting in a smooth flavor that retains natural texture. The larger teeth also reduce resistance, making grating effortless and cleanup as simple as rinsing with water.

The “Takumi Series.”

“The path of the grater is a ‘swamp,’” says Shinke. “With each one I make, a new door opens. There’s no precedent for what I’m doing, so the goal isn’t visible. At times I’ve nearly broken down from the pursuit, but now my vision is clear—I can see the path to being the best in the world. Even if I’m criticized or envied, I believe pushing craftsmanship to its limits will lead to the ultimate creation. I want to keep evolving every day, facing the grater, in pursuit of becoming number one.” (Takayuki Shinke)